Sump pumps and grinder pumps are critical components in residential and commercial water management systems, designed to efficiently remove wastewater and prevent flooding. These specialized pumps handle different challenges, from groundwater drainage to sewage transportation, utilizing advanced mechanical technologies to protect properties from water-related damage and ensure smooth waste disposal.

What Are Sump Pumps and Grinder Pumps?

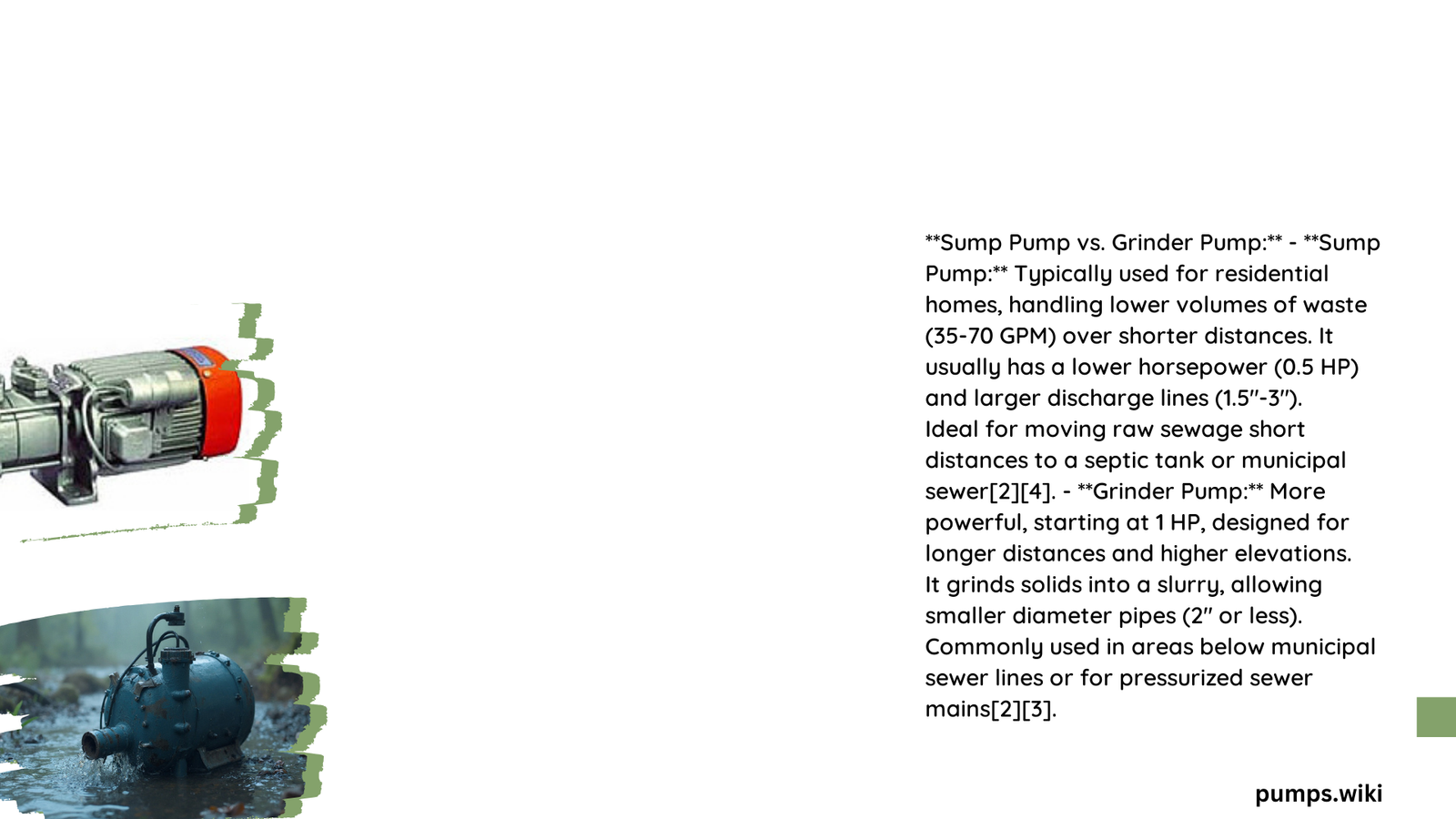

Sump pumps and grinder pumps serve distinct but essential functions in water management. A sump pump primarily removes excess water from basement areas, preventing flooding and moisture accumulation. In contrast, a grinder pump breaks down solid waste and pumps sewage from properties not connected to gravity-based sewer systems.

Why Do You Need a Sump Pump and Grinder?

Water Management Challenges

- Prevent basement flooding

- Handle wastewater in challenging terrain

- Protect property from water damage

- Ensure efficient waste disposal

Key Specifications for Liberty Grinder Pumps

| Model | Horsepower | Flow Rate | Max Head Height | Voltage |

|---|---|---|---|---|

| LSG202A | 2 HP | 3000 GPH | 100 feet | 208/230V |

| LSG202M | 2 HP | 50 GPM | 108 feet | 208-230V |

How to Install a Sump Pump and Grinder?

Preparation Steps

- Select appropriate pump model

- Gather necessary tools

- Prepare installation site

- Ensure proper electrical connections

Installation Process

- Measure sump basin dimensions

- Position pump correctly

- Connect discharge pipes

- Secure electrical connections

- Test system functionality

What Tools Are Required?

Essential Installation Equipment

- PVC pipes and fittings

- Pipe wrenches

- Electrical testing equipment

- Teflon tape

- Check valve

- Grounding equipment

Common Troubleshooting Scenarios

Potential Issues

- Pump clogs

- Electrical failures

- Unusual operational noises

- Reduced performance

Maintenance Best Practices

Regular Inspection Checklist

- Examine float switch

- Clean discharge pipes

- Check electrical connections

- Verify pump alignment

- Test system performance quarterly

Cost Considerations

Estimated Expenses

- Installation: $200 – $500

- Part replacements: $50 – $200

- Professional maintenance: $100 – $300 annually

Expert Recommendations

Professional Tips

- Always use dedicated electrical circuits

- Install check valves

- Perform regular maintenance

- Consider backup power systems

- Monitor system performance

Safety Precautions

Critical Safety Guidelines

- Disconnect power before maintenance

- Use proper protective equipment

- Follow manufacturer’s instructions

- Hire certified professionals for complex installations

Conclusion

Understanding sump pump and grinder systems requires comprehensive knowledge of their functionality, installation, and maintenance. By following professional guidelines and investing in quality equipment, homeowners can effectively manage water drainage and waste disposal challenges.